Centrifugal casting can be of three types namely centrifugal true centrifugal and semi centrifugal casting. This article discusses the mold design for different types of sand molds and permanent molds and their production considerations.

Tulsa Centrifugal Casting Machines Vertical Machines

The mould spinning speed depends on the casting desired.

. For this purpose a special design of a vertical axis centrifugal casting machine was developed. The design and fabrication of a centrifugal casting mach ine was successfully carried out. There is a difference between vertical centrifugal casting and horizontal centrifugal casting.

The first step is the vertical centrifugal casting of roll shellouter layer the second step is the vertical static casting of roll core. Gibson Centri Tech was established in 1980 by Douglas and Martin Gibson as a centrifugal casting machine design manufacturing and consultancy company. This method is more suitable for these bodies when the diameter is greater than their length.

We manufacture Horizontal Centrifugal Casting Machines Machine is designed primarily to accommodate and spin permanent steel moulds for large tube shaped castings. A detailed study of the centrifugal pouring process and. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA.

This project led to the design and construction of true centrifugal casting machine which is made of mould shaft belt pulley bearing motor. Centrifugal force is utilized to. With 40 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines.

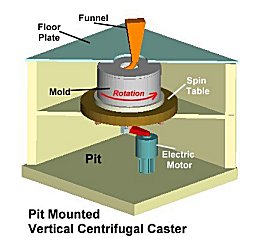

These heavy duty Vertical Axis machines are the workhorse of the centrifugal casting industry in producing a variety of ferrous and non-ferrous castings in a variety of shapes and sizes. Vertical centrifugal casting machines installed below the ground level for maximum operator safety are used for producing bushings and castings that are relatively large in diameter and short in length. Over 22000 Machines Sold Worldwide Since 1979.

For the horizontal centrifugal casting variable such as rotating ratio G aspect ratio thickness and vibration are studied to a sample of 1000 casting rolls made of casting iron. Vertical Centrifugal Casting Machine Mold diameter 3000 mm Production of gear rims for wind power plants KÜTTNER GMBH CO. Our machine designs produce castings in both ferrous and non-ferrous material from a few pounds.

Please visit the following links for more information or email our sales team salesgibsoncentritechcouk. High g-forces applied to the molten metal in the. Tulsa Centrifugal Casting Machines LLC founded by the leading centrifugal casting specialists in the USA.

Rs 20 Lakh Set Get Latest Price. What is vertical centrifugal casting. In this process mould is rotated rapidly about its central axis as the metal is poured into it.

Carl Küttner KÜTTNER has evolved into a worldwide group of companies working in plant engineering and construction. Gibson Centri Tech are based in Lichfield Staffordshire. From the vertical casting process we get superior mechanical properties and a more uniform fine grain structure of the manufactured component.

It is basically used for casting small hollow cylindrical components. It is capable of centrifugally casting cast iron alloy irons nickel chromium alloys. 34 For Medals Artifacts and Awards.

Capable of handling up to 100000 lbs 45359 kgs of dynamic loads with. The design setup is reduce the construction cost of machine. In centrifugal casting centrifugal force plays a major role in shaping and feeding of the casting.

Semi centrifugal casting is used to manufacture only the objects that are symmetrically shaped and the molds rotation axis stays in a vertical position for that. This video shows what happens during the centrifugal casting process. Ad Up to 40 x 20 x 20 Travels 43 x 20 Table 12K RPM 4th Axis Ready Fanuc 0i-MF Standard.

Vertical Centrifugal Casting Machines Further Information. A centrifugal casting machine in a safety ring with the burned out flask in place white cylinder eoeeeooeoeecasting machine with the casting flask A in position for melting metal prior to casting. Gibsons employees have a combined experience in centrifugal casting equipment of over two centuries.

Vertical Centrifugal Casting Machine Manufacturer Gibson Centri Tech Ltd. Centrifugal casting consists of a number of processes in which the centrifugal force set up by the rotation of a part of the casting is utilized to shape the casting fill the mould and help solidify and strengthen the metal Pavlovic et al 2009. With 45 years of experience in the Machine Design Manufacture Equipment Installation and Personnel training for Vertical and Horizontal centrifugal casting machines.

The operation of the machine was based on the principle of. After the static casting is finished the newly casted roll will be positioned in the ground pit for curing for 24 hours in a certain degreed temperature. Animation showing what happens during the vertical centrifugal casting processTo learn more about the centrifugal casting process visit us at httpswwwm.

In this method the mould is rotated in a vertically axis. In a centrifugal casting process the molten fuel alloy is poured vertically onto a rotating plate distributor where the melt flow turns to the horizontal direction. - This type of casting is followed for cylinder type bodies having ring geometry.

The vertical centrifugal casting process is used to cast cylindrical shapes whose diameter is more than the height or length of the cylinder. Ad Search Thousands of Catalogs for Vertical Centrifugal Pumps. When using a centrifugal casting machine the cost of thermal drying is reduced.

In Stock and Ready to Ship. The compact design of the centrifugal machine makes it ideal for small operating areas. Centrifugal casting machine is needed in the mineral processing industry to reduce waste and increase mineral separation efficiency.

A typical vertical centrifugal casting machine is shown in Fig. Our machine designs produce. Horizontal Centrifugal Casting Machine.

Components such as wheels sheaves pulleys and gear blanks are. Vertical Centrifugal Casting. The white disc in the foreground B is the hard asbestos steam head.

The two steps are proceeded continuously in sequence. The molds are aligned on the edge of the distributor and rotate with it. Centrifugal casting machines for ferrous and non-ferrous castings.

KG Originally an engineering company founded in 1949 by Dr. For the horizontal centrifugal casting two load envelopes are done being possible to determine the bearing model used on the vertical centrifugal casting machine.

Vertical Centrifugal Casting Machine

Vertical Centrifugal Casting Machine For Casting Rolls Federal Pipe Centrifugal Casting Machine Co Ltd

Constructive Scheme Of A Centrifugal Casting Machine With A Vertical Download Scientific Diagram

Vertical Centrifugal Casting Machine Download Scientific Diagram

Pdf Design And Development Of A Centrifugal Casting Machine For Pistons Production Semantic Scholar

Tulsa Centrifugal Casting Machines Vertical Machines

Schematic Of The Vertical Centrifugal Casting Machine Huang Et Al 16 Download Scientific Diagram

0 comments

Post a Comment